Applications:

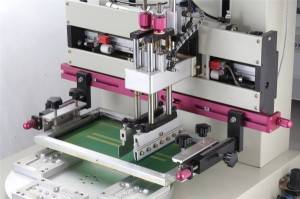

LP-S400F/S600F is suitable for screen printing on small industrial flat parts. Such as stamped metal panel, powder coated material, injection molded parts and much more.

Features:

1. Rotary working table driven by index cam, makes screen printing high output than single station machine.

2. Rotary working table can have 2/4/6/8 jigs.

3. The straight-up and down in the vertical plane, keeps the ink in the “print zone” right.

4. The flat vertical lifting method allows the operator to easily load and unload parts with the added advantage of being able to easily view and inspect the part.

5. Mitsubishi PLC and touch screen display.

6. Dual axis driven by AC motor or pneumatic.

7. Loading and unloading robot are optional.

Specifications:

|

Model |

LP-S400F |

LP-S600F |

|

Driven method |

Pneumatic |

Electric |

|

Max. printing are |

100*150mm |

150*250mm |

|

Working table size |

250*400mm |

150*250mm |

|

Jigs |

2/4 |

2/4/6 |

|

Max. printing speed |

1600 cycles/hour |

2200 cycles/hour |

|

Voltage |

110/220/230 50/60HZ |

110/220/230 50/60HZ |

|

Air pressure |

5-7 bar |

5-7 bar |

|

Machine weight |

180kg |

320kg |

|

Machine dimension |

L580*W780*H1350mm |

L1000*W1250*H1550mm |