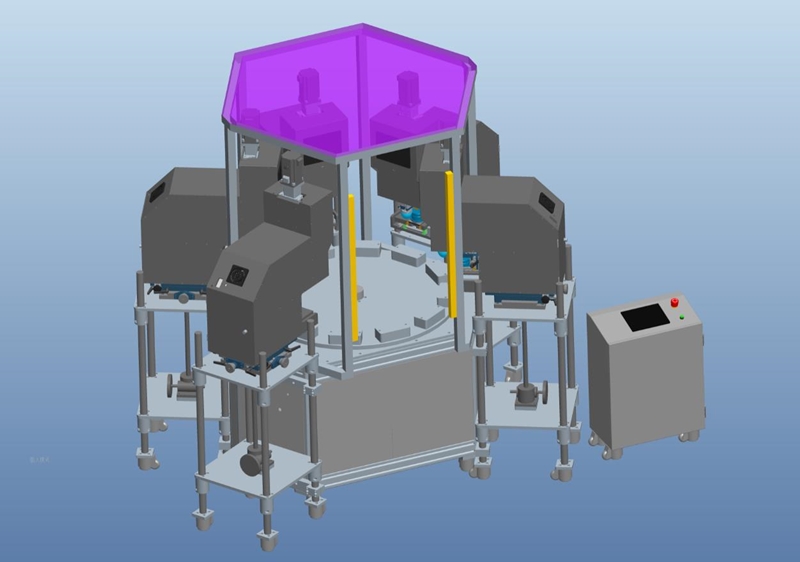

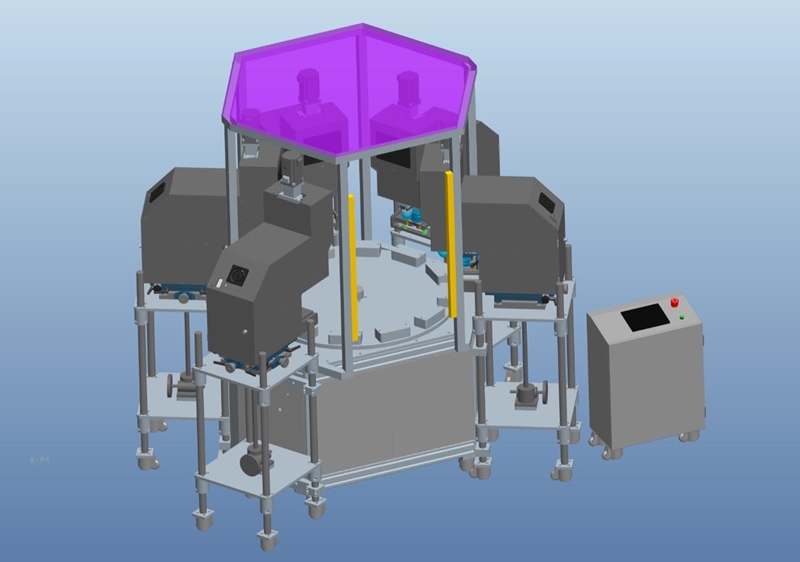

High precision fully electric servo motor pad printing machine

Infeed and outfeed manual by hand;

Printing system:

1). Controll system:

Mitsubishi PLC and touch screen display;

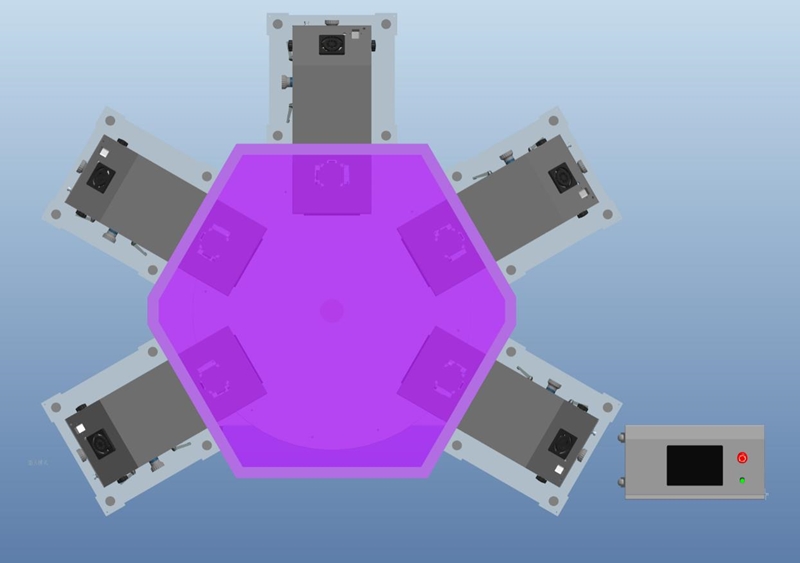

2). 5 head, head is movable back/front/sides, up/down;

X adjustment 15mm on each side by hand;

Y adjustment 30mm forward and back by hand;

Multiple stroke by PLC control; Stroke is set by digital on touch screen display.

Head strokes adjustable;

Infinitely variable speed for stroke; Speed is set on touch screen display from 1-9 speed;

3). Indexing table ( Taiwan DEX brand):

12 stations, holes for bolts and dowels; (Customer provide hole’s distance, hole’s diameter for mount jigs)

Rotary table with infinitely variable speed;

12 Jigs position accuracy not less than +/- 0.03;

Rotary stop position accuracy +/- 0.03;

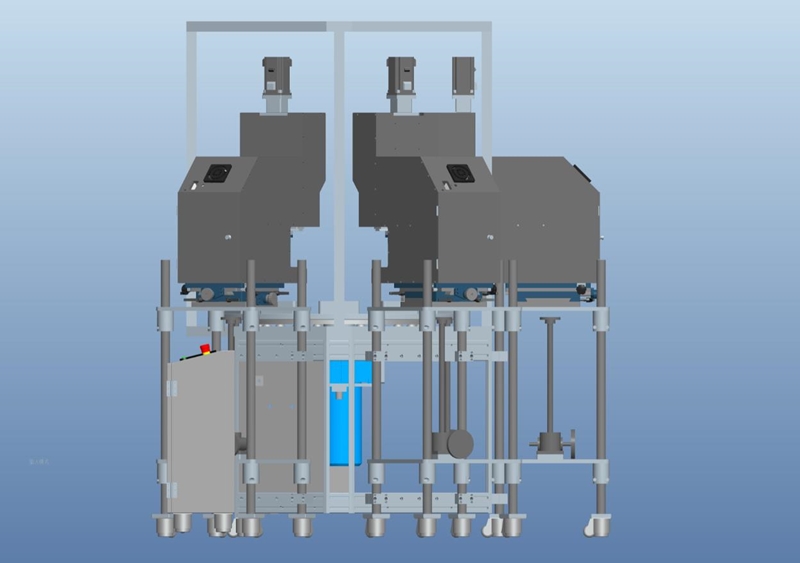

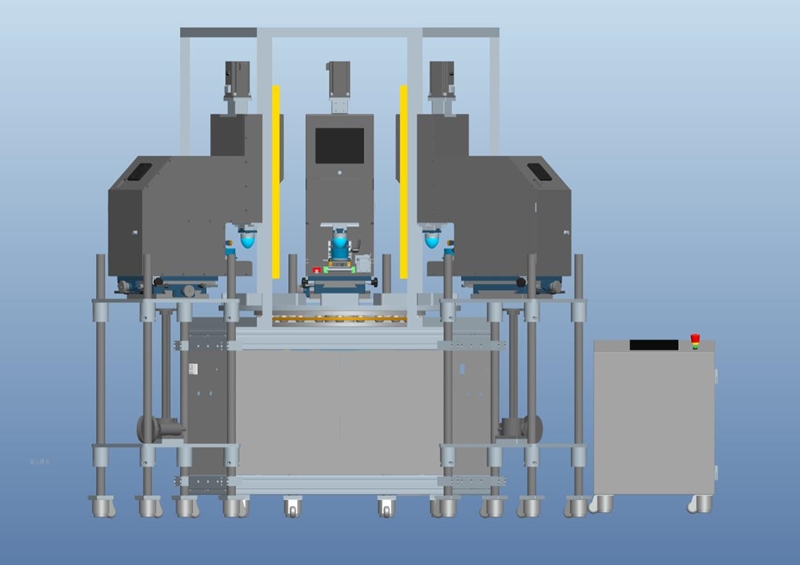

4). Pad motion method: up and down driven by Panasonic servo motor;

5). Steel plate motion method: forward and backward driven by Panasonic servo motor;

6). Pad cleaning driven by stepper motor;

7). Hot air drying system (Blower, heater (Germany brand), temperature controller (Omron brand));

8). Option to use one machine or more;

Main machine has a control center to control all 1-5 heads, each head not have control system respectively.

Specifications:

Ink cup size: 90mm with carbide blade;

Cliché size: 100*200mm;

Printing image size: Est ¢75mm;

Printing speed: 1000-1200 pcs/h;

Accuracy: ±0.05mm;

Machine diamension: L 2084*W 1804*H 2028mm;

“Power; 220V-400V/AC 50HZ.

Air blast for hot air drying: 1kw/h;

Each head: 1.5wk/h;

Indexing table: 400w/h;”

Safety guards:

Emergency stop for the whole machine;

Each head has a stop button;

To have side doors for machines access;

Safety doors, and optical grating, 3 colors LED alarm lamp;